Spacer Types: The Small Parts That Make IGUs Ultra-Efficient

When it comes to high performance glazing, most people think of the obvious features: coatings, double and triple glazing, advanced laminates and high performance frames. But the truth is, even the smallest components can have a big impact. One of the most important – yet often overlooked – are warm-edge spacers.

Why Spacers Matter

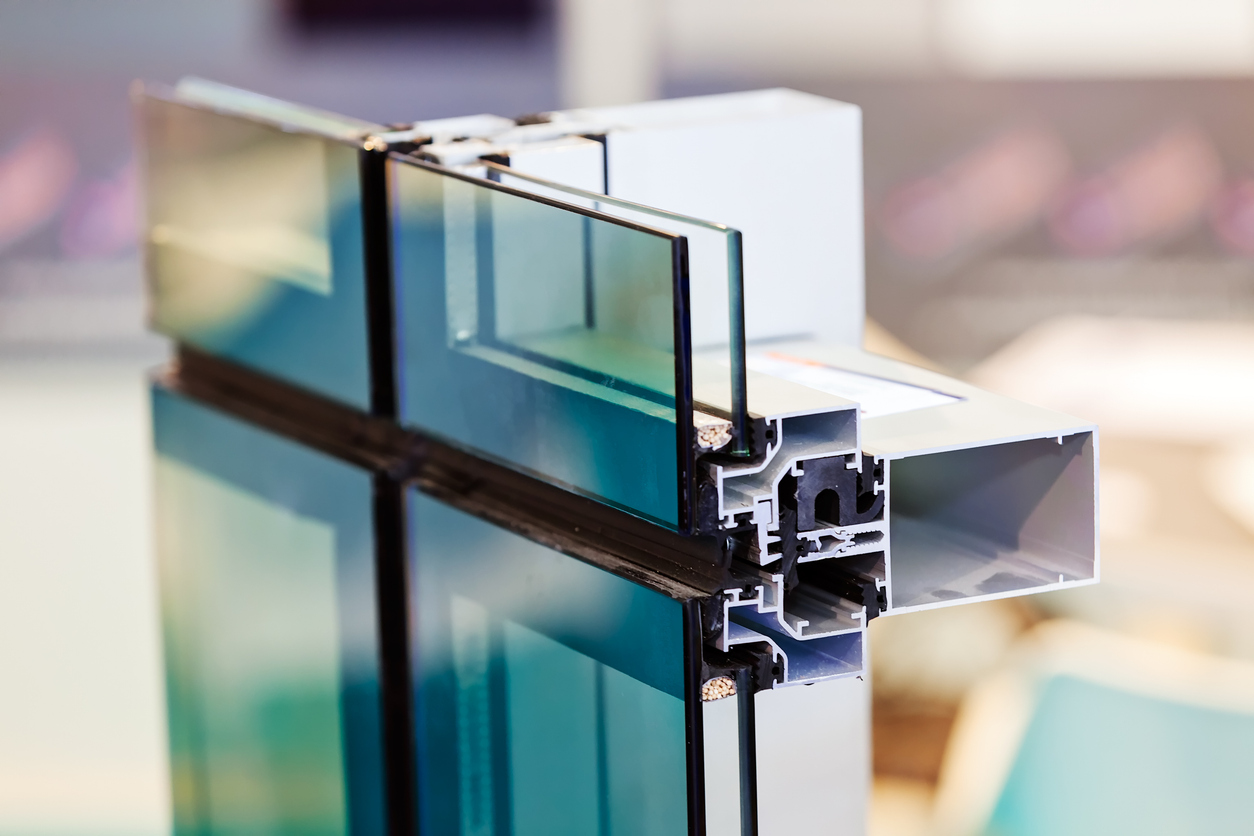

Spacers sit between the panes of glass in Insulated Glass Units (IGUs), keeping them apart and maintaining a precise cavity. This cavity is then filled with either air or an insulating gas like argon. It plays three key roles:

- Reducing heat transfer through the unit edges.

- Minimising condensation build-up on glass edges.

- Boosting durability and thermal performance of the IGU overall.

Traditional aluminium spacers, while lightweight and easy to fabricate, conduct heat and cold easily. This creates a thermal bridge that reduces energy performance and often causes condensation. That’s where warm-edge technology steps in.

What Are Warm-Edge Spacers?

Warm-edge spacers are made from low-conductivity materials that significantly reduce heat transfer. They’re designed to break the thermal bridge created by aluminium, making windows far more efficient.

At Viridian, we offer three warm-edge options:

- TPS™ (Thermo Plastic Spacer): A UV-stable, butyl-based spacer applied directly to glass with an integrated desiccant.

- Super Spacer™: A metal-free silicone foam that delivers outstanding thermal performance.

- Rigid Composite (Plastic/Stainless Foil): A non-metal spacer with a high-quality foil finish for a clean, consistent look.

The Benefits of Warm-Edge Spacers

Switching to warm-edge spacers isn’t just a technical upgrade – it’s a comfort upgrade too. Here’s why:

- Better Energy Efficiency: Reduces heat loss and improves U Values.

- Condensation Resistance: Keeps glass edges warmer, reducing the chance of condensation.

- Improved Comfort: No more cold spots near windows.

- Certified Performance: All Viridian warm-edge spacers are Passive House certified.

Our focus on sustainable innovation makes warm-edge technology a natural fit.

Spacer Highlights

- TPS™

- Flexible for curved and complex shapes.

- Forms a seamless, durable seal.

- Highly resistant to moisture and gas diffusion.

- Automated application ensures consistent quality.

- Matt black finish.

- Super Spacer™

- Lowest thermal conductivity in our range.

- Applied robotically for consistent quality, even in large units.

- Perfect for non-rectangular shapes.

- Clean matt black finish.

- Rigid Composite

- Works with existing aluminium spacer equipment.

- Looks similar to traditional aluminium.

- Semi-gloss black finish.

The Efficiency Edge

Warm-edge spacers can cut window U Values by up to 0.2 – a big advantage when fabricators and glaziers are chasing higher energy ratings. When combined with performance glass and thermally improved frames, this offers an affordable way to meet tougher efficiency standards.

At Viridian, we’re committed to extending performance right to the edge of every panel. With warm-edge spacers, your IGUs aren’t just functional – they’re future-ready.